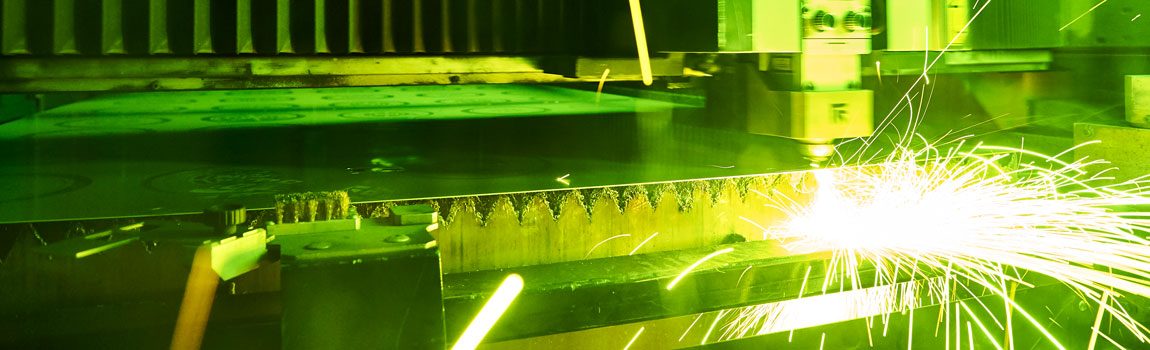

LASER CAPABILITIES

At Malach, we make our in-house nitrogen, the gas that powers our lasers; this represents significant cost savings – savings we pass on to you!

We provide laser-cutting services from the lightest gauge to 5/8" of aluminum and several types of steel through a 24/7 automated operation. All laser-cutting systems are integrated with the design software, which ensures quick, accurate translation of our client's designs into our laser operation. As a value-added service, we also undertake the assembly of laser-cut parts.

Our fully-automated Finn Prima-Power 6 kW fibre-optic laser is used to cut a wide range of materials, including stainless, cold-rolled and galvanized steel and aluminum. Automated loading and unloading, combined with a fast and powerful laser head, results in a quick turnaround of each customer's order with precise tolerance. Along with our Finn-Power L6 laser, this laser brings sophistication in high-speed laser-cutting to a new level, creating enhanced production with superior speed, accuracy, and part quality. Both lasers have been designed using innovative linear drive motor technology to allow maximum speeds, even in small notches or narrow contours. They provide previously unseen high-speed performance concerning machining dynamics, contour accuracy, and process safety. Finn-Power L6 will process sheet sizes up to 1565 mm x 3074 mm (60" x 120").

Our Trumpf TruLaser 5030 Classic 5000 Watt flying optic laser has the following capabilities:

- Laser output: 5000 watts, X-axis travel: 120", Y-axis travel: 60", Z-axis.

- Travel: 4. 5" max. Workpiece weight 1980 lbs. max.

- Material thickness (mild steel) 1" max. Material thickness (stainless) 75" max.

- Material thickness (aluminum) .6" max.